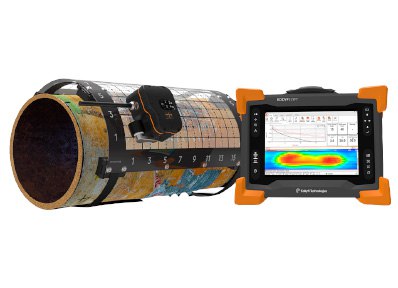

Pulsed Eddy Current Testing – PECT

Pulsed Eddy Current Testing – PECT is a rapid screening corrosion assessment (remaining % thickness measurement) method utilized primarily on insulated ferrous pipelines, tanks & vessels eliminating the operating asset’s downtime.

Corrosion survey without removing up to 150mm thick insulation on the test surface having temperature up to 550 degrees Celsius (hot or cold)

Measure wall thickness through any non-conductive insulation materials such as natural fibers, asbestos, fireproofing, coatings, ceramic, concrete, brick, foam, wool, pharmocol, bitumen, etc.

Measure thickness through galvanized, stainless, aluminum, cladding or weather jacket

Measure thickness through chicken or hog wire reinforced insulation, straps or protective and polymer coating

No need for surface preparation (scan over corrosion scab or blister) thus minimized risk and cost saving for the plant owner by avoiding grinding or removal.

Measure thickness from 4 to 65mm on pipes above 75mm diameter or vessels or spheres or support legs.

No need for scaffolding. Remote control inspection using extension arms up to 4.6m height.

Battery powered instrument. Perfect for remote locations.