MFL floor mapping

The Floor map VS2i, a computerized magnetic flux leakage system designed to detect, size and map underfloor corrosion on above ground storage tanks. The Floor map VS2i magnetic flux leakage (MFL) floor scanner comes with up-graded magnets to improve corrosion detectability and sizing on thicker materials, faster data capture with a custom designed micro controller and all new software. The Floor map VS2i contains significant improvements in terms of defect positioning, electronic data processing and software manipulation.

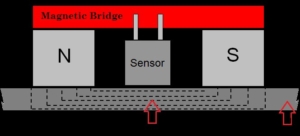

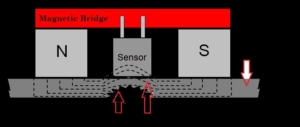

Theory of operation

As floormap v2si moves forward, powerful permanent earth magnets which maintained at the bottom of the scanner, induces localized magnetic saturation at the tank floor plates, as the scanner moves over the area of corrosion, an array of 32 hall effect sensors mounted between the two magnet poles sense changes in the magnetic field, which then converted into electrical signals, the electrical signals is then processed before being sent to the on-board computer, once the scan has been saved, the location and severity of the corrosion is displayed on the color coded map of the plates.

Characteristics

• Detect corrosion using 32 hall sensors.

• Scan width is 250 mm.

• Method of propulsion is by DC motor.

• Speed is 0.5 m/ sec.

• Thickness range is 12.5mm maximum in case of automated sizing mode and 20 mm maximum in case of detection mode.

• The test could be performed through coating up to 6 mm thickness.

• Sensitivity is Adjustable up to 20% underfloor corrosion on coated 6 mm plate or 10% underfloor corrosion on uncoated 6 mm plate.

• The MFL Floormap v2si is provided with auto-stop upon detection option and real time analysis.

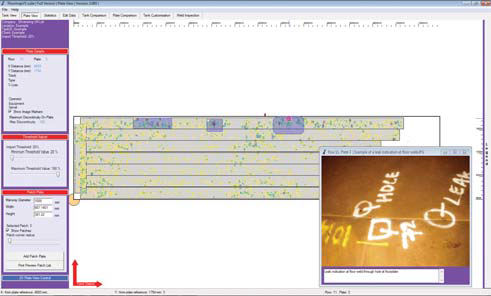

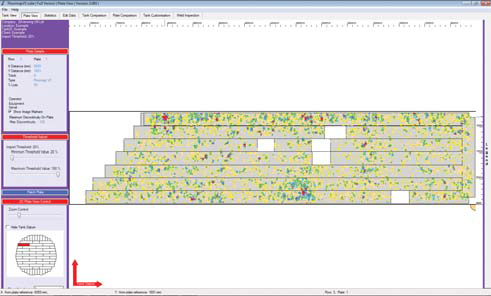

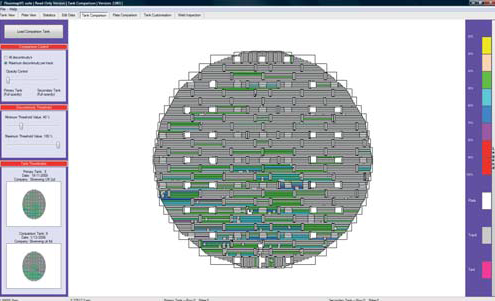

Reporting

• The off-line reporting software automatically produces a CAD drawing of the tank floor with the defects being positioned to within 3 mm accuracy. All captured data, over 20% loss of the nominal plate thickness, is re-analysed to identify the defect profile and separate the corrosion into 1 of 3 classes. Different sizing algorithms are applied to each class of corrosion ensuring enhanced defect sizing even on badly corroded floors where small diameter deep pits may otherwise have been undersized.

• Additional data from visual, ultrasonic, vacuum box and magnetic particle inspection can be added to the report generating a full fingerprint of the tank floor including the annular plates. An innovative feature of the software allows subsequent inspection data to be overlaid and corrosion growth identified.

• These features coupled together with a patch plate design function and full statistics package give a powerful, cost effective tool with which to carry out trending and asset life projections.

• Measurement tools for sizing areas of corrosion.

• Top / Bottom defect views.

• Ability to add previous inspection for comparison.