PAUT

Phased Array is the most recent progressed Ultrasonic innovation that works by a computer-controlled excitation of individual components in a multi-element transducer. In brief, Staged Cluster produces numerous ultrasonic signals, in nanoseconds, that deliver controllable points, center profundities and/or wide scope from one assessment point. Read more…

LONG RANGE ULTRASONIC TEST (LRUT)

Long Range Ultrasonic Testing (LRUT) is an advanced non-destructive testing (NDT) method designed to inspect the integrity of materials, particularly pipes and pipelines, over extended distances. Unlike conventional ultrasonic testing, which is limited to short-range inspections, LRUT utilizes low-frequency ultrasonic waves to cover large areas from a single inspection point. Read more…

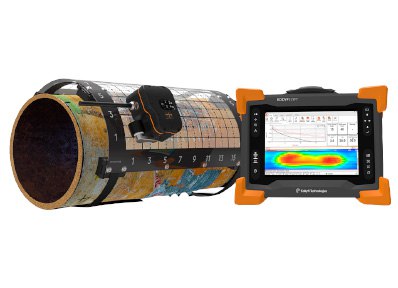

Short Range Ultrasonic Testing (SRUT)

Short Range UT works based on the principle of sending high-frequency ultrasonic waves into the material and analyzing the reflected signals to detect defects. It involves using a small, handheld probe that emits and receives ultrasonic waves. The probe is placed directly on the surface of the component being inspected Read more…

Pulsed Eddy Current Testing – PECT

Pulsed Eddy Current Testing – PECT is a rapid screening corrosion assessment (remaining % thickness measurement) method utilized primarily on insulated ferrous pipelines, tanks & vessels eliminating the operating asset’s downtime.Corrosion survey without removing up to 150mm thick insulation on the test surface having temperature up to 550 degrees Celsius (hot or cold) Read more…

Tube Inspection

Eddy current testing of tubes is an effective way of assessing the condition and lifespan of tubes, particularly in the power generation, petrochemical, chemical, fertilizer and air conditioning industries. The technique is applied to detect corrosion, pitting, cracks, erosion and other changes to both the tube’s interior and exterior surfaces. Read more…

Thermography

In engineering, thermography is used as a non-destructive testing (NDT) method in aerospace, defense and many other industries to detect flaws in structures. Able to inspect large areas, this NDT technique doesn’t require contact with the object being tested and can highlight defects including corrosion; cracking; delamination Read more…

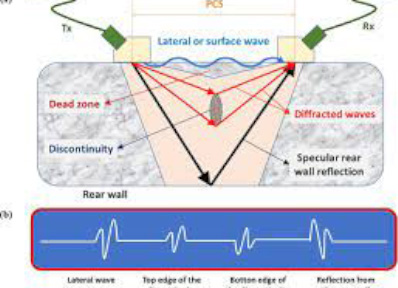

Time of Flight Diffraction (TOFD)

Time of Flight Diffraction (TOFD) is a reliable method of nondestructive ultrasonic testing (UT) used to look for flaws in welds. TOFD uses the time of flight of an ultrasonic pulse to find the location of a reflector. It can also be used for weld overlays and the heat affected zones of other components as well such as piping Read more…

MFL floor mapping

The Floor map VS2i, a computerized magnetic flux leakage system designed to detect, size and map underfloor corrosion on above ground storage tanks. The Floor map VS2i magnetic flux leakage (MFL) floor scanner comes with up-graded magnets to improve corrosion detectability and sizing on thicker materials, faster data capture with a custom designed Read more…

Ground Penetration Radar (GPR)

Just as the first MALÅ Easy Locator revolutionized the utility locating industry to become the industry benchmark for GPR utility location, MALÅ Easy Locator HDR is a game changer. The High Dynamic Range, or HDR, is the next generation in MALÅ GPR technology specifically optimized for utility location. MALÅ Easy Locator HDR is faster Read more…

CIPS/DCVG Survey

A direct current voltage gradient (DCVG) survey is a type of survey method that is used to assess the efficacy of corrosion protection, particularly on structures buried underground This is highly useful in the natural gas and oil industries, as this technique is used to trace coating faults Read more…